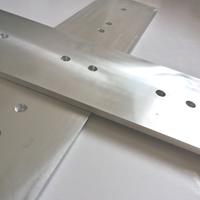

Sanadihii la soo dhaafay, iyada oo horumarka tignoolajiyada isku-dhafka ah ee isku-dhafka ah (IC), codsiyada la xidhiidha wareegyada isku-dhafka ah ayaa si degdeg ah loo horumariyay.Nadiifinta sare ee aluminium aluminium yoolka, oo ah walxo taageeraya wax soo saarka isku-xidhka birta wareegga ah ee isku-dhafan, ayaa noqotay mawduuc aad u kulul cilmi-baadhis gudaha ah ee dhawaanahan.tifaftiraha RSM ayaa ina tusi doona sifooyinka saafiga sare ee aluminium aluminium yoolka sputtering.

Si loo sii wanaajiyo waxtarka xajinta ee bartilmaameedka magnetron-ka iyo in la hubiyo tayada filimada la xareeyay, tiro badan oo tijaabo ah ayaa muujinaya in ay jiraan shuruudo gaar ah oo loogu talagalay halabuurka, qaab-dhismeedka yar-yar iyo jihaynta hadhuudhka ee ultra-sare nadiifinta aluminium aluminium yoolka.

Cabbirka hadhuudhka iyo jihaynta hadhuudhka ee bartilmaameedku waxay saamayn weyn ku leeyihiin diyaarinta iyo sifooyinka filimada IC.Natiijooyinku waxay muujinayaan in heerka dhigaalka hoos u dhaco korodhka cabbirka hadhuudhka;Hadafka qulqulaya ee leh halabuurka isku midka ah, heerka qulqulka ee bartilmaameedka leh cabbirka yar yar ayaa ka dhaqso badan kan bartilmaameedka leh cabbirka weyn;Inta lebbiska ah ee cabbirka hadhuudhka bartilmaameedka, ayaa sii badanaya qaybinta dhumucda filimada la kaydiyay.

Marka la eego isla qalabka wax lagu shubo iyo cabirrada habka, heerka xajinta ee bartilmaameedka Al Cu wuxuu kordhiyaa kororka cufnaanta atomiga, laakiin guud ahaan wuu xasilloon yahay baaxad ahaan.Saamaynta cabbirka hadhuudhka ee heerka sputtering waxaa sabab u ah isbeddelka cufnaanta atomiga oo leh beddelka cabbirka hadhuudhka;Heerka meel dhigista waxaa inta badan saameeya jihaynta hadhuudhka ee bartilmaameedka Al Cu alloy.Iyada oo ku saleysan hubinta saamiga (200) diyaaradaha crystal, kororka saamiga (111), (220) iyo (311) diyaaradaha crystal waxay kordhin doontaa heerka dhigaalka.

Cabbirka hadhuudhka iyo jihaynta hadhuudhka ee bartilmaameedyada daawaynta aluminium daahirnimo ee aadka u sarreeya ayaa inta badan la hagaajiyaa oo lagu xakameeyaa isku-duubnida, shaqaynta kulul iyo dib-u-kicinta.Iyada oo la horumarinayo cabbirka waferka ilaa 20.32cm (8in) iyo 30.48cm (12in), cabbirka bartilmaameedku sidoo kale wuu sii kordhayaa, kaas oo soo bandhigaya shuruudo sare oo loogu talagalay bartilmaameedyada qulqulaya aluminium nadiif ah oo aad u sarreeya.Si loo hubiyo tayada filimka iyo wax-soo-saarka, waa in si adag loo xakameeyo cabbirrada hab-socodka bartilmaameedka si loo sameeyo qaab-dhismeed yar oo bartilmaameed ah iyo hanuuninta hadhuudhku waa inay lahaataa mid xooggan (200) iyo (220) textures diyaarad.

Waqtiga boostada: Juun-30-2022